CHALLENGE

Designing confidence, not just a bus trial

Arrival was preparing for its first bus trials with customers in the North of England with 2 buses. We were tasked with shaping an end-to-end service experience that would give skeptical depot operators—used to diesel fleets and decades-old processes—a reason to trust something radically new. We had to build a customer trial experience for electric buses—designed not as a test drive, but as proof that the product could embed seamlessly into a working depot.

The goal? A fully integrated trial where customers could run our buses in their own depots, with their own drivers and technicians, for two to four weeks. But very little existed – we were doing this for the first time: no onboarding flow, no operational manual, no support model, no clear handoffs across internal teams. What started as a customer experience mapping brief quickly expanded into designing the service offer itself—defining everything from physical delivery steps to digital troubleshooting channels, all the way to post-trial wrap-ups. We had to bridge three major gaps:

- The customer gap: fleets unsure about electric performance and digital complexity.

- The operational gap: trial coordination spread thin across servicing, engineering, and sales.

- The trust gap: no prior evidence to show we could deliver at scale.

Our work needed to create alignment inside the company and assurance outside it. That meant designing with the full ecosystem in mind—from the person receiving the bus to the one chasing a charging fault three days in

CONTEXT

How fleets are sold

For commercial vehicles- fleet deals usually mean orders of 10, 50, sometimes 500 vehicles. And with that kind of scale, the margin for uncertainty is close to zero. Trials become an important step in the sales journey. They are “operational audits” before such a big purchase. Fleet managers, depot technicians, drivers—they aren’t looking for bells and whistles. They look for minimal downtime, clear support processes, and trust that onboarding wouldn’t turn into a headache. The trial is the perfect opportunity to demonstrate all of this—seamlessly, end-to-end.

We had to prove that the bus would work in the real world—charging, routing, servicing, everything and that it could do so without disrupting the carefully balanced workflows of depot operations. With Arrival the stakes were higher. We weren’t offering a standard fuel-and-play bus. We were offering a new category: an electric bus, with a digital interface, a modular design, and no legacy to lean on.

APPROACH

HMW sit inside the depot’s day-to-day without chaos, confusion, or calls at midnight

Understanding the Real World (and the Real People Running It)

We kicked things off in classic double diamond form—but this was no template job. Our discovery phase was deep and physical. We needed to understand what it actually takes to run a depot: who does what, how information flows, what “normal” looks like at 6am on a wet Tuesday when a bus doesn’t start.

We ran co-creation workshops and remote Miro sessions. We did ethnographic research onsite in the North, mapping operational rhythms, pain points, and daily rituals. We dug into everything—driver routines, charge point availability, maintenance scheduling, comms protocols. And we looked inward too: dissecting Arrival’s internal plans, surfacing gaps between vision and delivery.

This phase wasn’t just about learning—it was about earning trust. The fact that we showed up in person, listened, iterated live—it gave us room later on to challenge assumptions and propose new behaviors.

Fig.1 – Photos from field research in bus depots

Making Sense of Depot Logic

Within weeks, we had a working model of depot life—enough that we could’ve probably opened our own. We mapped 15 critical moments that any trial needed to deliver flawlessly: daily checks, overnight charging, fleet handovers, fault escalation, end-of-day reporting.

More importantly, we understood where our offering could slot in and add value. For example: Arrival’s sensor-driven maintenance data meant fleet managers could skip manual inspections and get a real-time health snapshot by 6am. That wasn’t just a nice feature—it was a workflow upgrade.

We also knew where friction would show up. The vehicle was different—new interface, new behaviors. Drivers needed upfront training, and fleet staff needed time to adjust. Raising these early gave our trial team leverage: we weren’t just delivering buses, we were helping evolve depot culture.

By embedding ourselves in their world, we made the trial feel collaborative—not imposed. That shift in tone unlocked a better working relationship and gave Arrival’s internal teams the confidence to own the delivery.

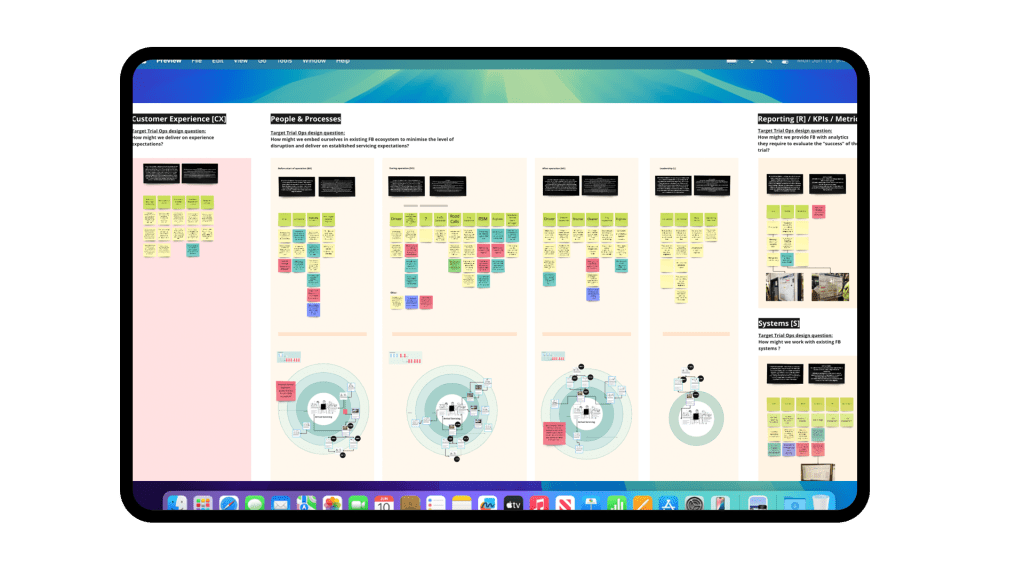

Fig.2 – A visual sample of the key trial scenarios

Fig.3 – A visual sample of the trial blueprint

Fig.4 – A visual sample of ideation workshop

Prototyping the Trial Experience

Once we had a solid understanding of what needed to happen, we moved fast into prototyping. This was a rare moment to design a physical experience not a set of screens—we leaned on process maps and scrappy visuals. Think: service journey meets board game. Each “map” showed how a core slice of the trial would play out—who did what, when, and with what tools.

We mocked up experiences that captured real scenarios: what happens when a bus breaks down mid-route? How do depot staff log faults? When does Arrival step in—and how?

These maps were simple but powerful. They let teams visualise the invisible: information flows, handoffs, and fail-safes. We stress-tested them with internal teams and with customers. Feedback loops were tight. Every round, we sharpened the offer.

From this work emerged the operations manual—a living document that laid out the entire trial playbook. It was structured enough for consistency, flexible enough for local differences, and visual enough to keep everyone—from engineers to depot managers—on the same page.

Fig.5 – A visual sample of the trial operational manual prototype

IMPACT & OUTCOMES

A departure from headline metrics that don’t say enough – Product and service owners need meaningful insights

£150,000+ operation de-risked

Our work gave leadership confidence to launch—turning a high-stakes pilot into a controlled, coordinated delivery. That’s an expensive lesson avoided.

4–6 saved weeks per future trial

No more starting from zero. For each new trial, teams could reuse, adapt, and deploy a tested structure—cutting planning time and cross-team alignment effort significantly.

A step-change in customer trust

Customers told us, explicitly, that no other manufacturer had taken this much care to understand how they actually work. That translated into more transparent conversations, openness to change, and a deeper willingness to embed our product into their long-term plans.