CHALLENGE

Building End-to-End Support for Electric Commercial Fleets

Arrival wanted to flip the script. Instead of treating after-sales like an afterthought, they aimed to design one of the first fully digital, end-to-end servicing platforms for commercial EVs—uniting diagnostics, repairs, part orders, scheduling, and warranties into one cohesive system.

But this wasn’t just a build—it was a rethink. What does “all-in-one” actually mean when you’re dealing with decades of maintenance across regions? What workflows need redesigning? What matters to the people on the ground?

My job was to help answer those questions. I worked across the UK, North America, and the EU to map the real servicing journeys, uncover pain points, and shape a platform rooted in user needs—not assumptions.

CONTEXT

The Long Life of a Commercial EV

After a commercial electric van or bus rolls off the lot, its real life begins. These vehicles stay in service for up to 25 years, enduring daily wear from transit loops, delivery routes, and depot runs.

Maintenance is constant—daily checks, monthly tune-ups, annual inspections, parts replacements, system patches. But unlike your average car, these vehicles are stitched into critical services. A broken ramp or delayed repair isn’t just an inconvenience—it’s a disruption.

And the servicing landscape? Fragmented. Fleet operators often juggle multiple vendors, specialists, and warranty conditions just to keep vehicles road-ready. Something as small as a ramp rewire can spiral into a two-week ordeal—burning time, money, and trust.

APPROACH

Zero to One

Building the Baseline

This wasn’t just a blank slate—it was a vast, fragmented terrain. With teams scattered across the UK, North America, and the EU, and no shared view of what “after-sales” even meant, the first step was getting everyone on the same page.

I started solo. In the first week, I ran rapid research sessions with country-level after-sales leads to surface a working list of every product and service they wanted to offer—from warranty and predictive maintenance to technician training and health diagnostics.

From there, I launched a marathon of 10 workshops with functional teams: warranty, servicing, over-the-air updates, manuals, and more. I also tagged along to customer site visits to understand real-world operations and bottlenecks. Layered on top of that was a heavy dose of market research to track trends in EV servicing and spot emerging gaps.

The result? A comprehensive end-to-end map of every journey, touchpoint, and service function across the after-sales lifecycle. I created a central archive of user needs, process flows, competitive benchmarks, and design gaps—an “after-sales bible” that became the go-to reference for the entire organisation. For the first time, Arrival had a clear picture of what an all-in-one servicing platform could and should look like.

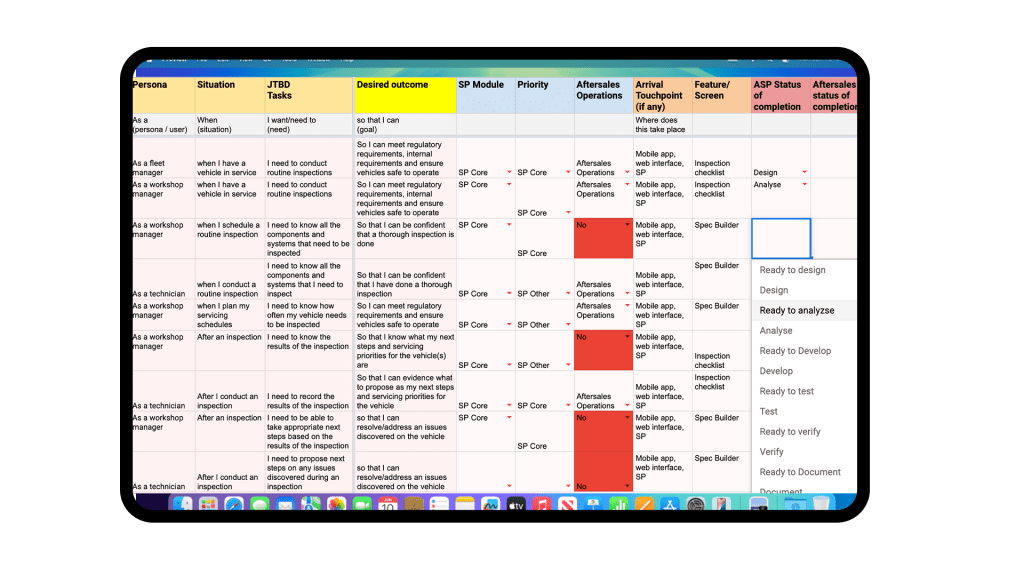

Fig.1 – A visual sample of the end to end after-sales offering

Shaping Strategy Through Evidence

Building everything wasn’t an option. So the next step was focus.

I helped product and service leads cut through the noise and zero in on what really mattered—features with high customer impact, regulatory necessity, or strategic value to Arrival (like owning the warranty experience). We used rapid prioritisation workshops, combining stakeholder input, customer insights, and current journey maps.

To bring those to life, I ran cross-functional workshops with 12 domain experts to map out how each part of the business contributed to user outcomes. We translated these into 650+ user stories, which we prioritised by production timelines, operational risk, and business value.

Fig.2 – A visual sample of the user story backlog

Mistakes were made. Our initial attempt to gather every requirement upfront was waterfall in disguise—overwhelming to devs, PMs, and even the CTO. I course-corrected by working with teams to segment the scope by functional area, allowing us to move in more manageable sprints and build confidence incrementally. This exercise distilled the vision into 60 core user scenarios we needed to deliver first.

Fig.3 – A visual sample of the key after-sales scenarios

Prototyping at Speed, Testing with Purpose

With the strategy in place, we shifted into build mode.

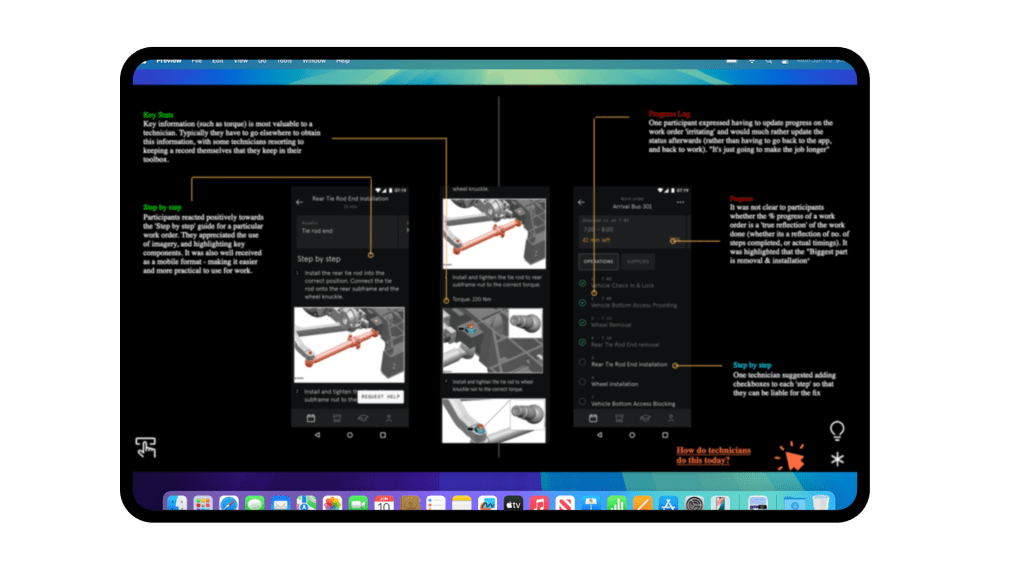

I partnered closely with interaction designers and user researchers to prototype and test key journeys across desktop and mobile—covering everything from service monitoring and repair scheduling to technician training and parts management.

We set up a 6-stage testing framework, ran co-creation workshops, and validated flows through internal pilots and external testing with SMEs and real customers across regions.

Fig.4 – A visual sample of the user testing of platform features

While the product wasn’t yet a fully integrated platform, it was a massive leap forward: we had tested journeys with functional apps in the hands of users, a validated roadmap, and real buy-in from internal teams. After 8 months, we handed over a solid foundation—one that teams could confidently build on, test, and scale..

IMPACT & OUTCOMES

Confidence amidst complexity

£450K+ in cost avoidance

By building a clear baseline and validated product strategy before jumping into development, we avoided at least 4–5 months of wasted engineering effort, misaligned backlogs, and premature tooling decisions—saving hundreds of thousands in delivery costs and rework.

Roadmap Clarity for Tech & Ops

Synthesised 650+ user stories and distilled them into a phased roadmap and feature specification list—used to guide software development, vendor sourcing, and operational budgeting across regions.

From Fog to Framework

Created Arrival’s first comprehensive map of the end-to-end after-sales experience—spanning 10+ functions, 60 key scenarios, and hundreds of processes—giving global teams a shared reference point to align, plan, and prioritise.