I. The Morning Report

Lima didn’t love Mondays, but she liked them. They had shape.

She was in her kitchen pod—one of those prefab studio flats squeezed onto the roof of a former Debenhams—eating overnight oats with a splash of cardamom oat milk and scrolling through alerts on her slate. She managed eight ghost factories across the UK. It sounded cooler than it was.

Each factory made spare mechanical parts. Print-on-demand. Very boring. Very profitable. Seals, gaskets, driveshafts, the occasional part for a discontinued bus line. Her factories were 10,000 square feet each, dotted around city edges like forgotten IKEA returns.

By 9am, she was on the train to Nunhead-4, earbuds in, her manager droning through the weekly stand-up.

“Don’t forget the new compliance sheets,” said Roy, who used to work in retail footwear before getting a job at SilentForm Industries through a cousin. “The board’s big on traceability this quarter. No rogue parts.”

Lima sipped her coffee. Roy once asked her if “the printers use ink or glue.”

II. Welcome to Nunhead-4

Nunhead-4 sat behind a disused mail depot and a 24/7 tanning salon. From the outside, it looked like a warehouse married a shipping container and got divorced immediately. Inside, it was clean, modular, and silent. Air smelled like filtered plastic and cedar—someone had installed one of those mood humidifiers, probably Evie.

Evie was the CAD Steward. She had an art degree and a side hustle in biodegradable jewelry. Smart. Underpaid.

Jonas did ops—receiving supplies, dispatching orders, checking print arms for stray crumbs. He’d once dropped an entire crate of filament reels because he was watching a synthpop concert livestream during unloading.

“Morning, boss….breakfast?” he grinned, handing Lima a misprinted sprocket as a joke. She smiled politely and slipped it into her coat pocket. Her visits were short—routine catch-ups, maintenance logs, human contact.

It was 10:14am when everything shut down.

III. No One Panic (Everyone Panics)

Lights off. Doors sealed. Fans stopped. All terminals dead. Even the mood humidifier clicked and let out a sad puff.

A red line appeared across the floor.

SECURITY LOCKDOWN. NETWORK ISOLATED.

No signal. Not even for emergency channels.

Lima blinked.

“Is this… supposed to happen?” Jonas asked, holding a crate like a medieval shield.

“No,” said Evie flatly. “Not unless someone tried to override the print stack.”

Lima tried her slate. No connection. No override options. No Roy, thank god.

“What now?” Jonas asked.

Lima wanted to say something manager-y. She ended up saying:

“Let’s… just not touch anything.”

IV. The Not-So-Silent Intrusion

It was Evie who found it.

Buried under a routine part order, someone had been printing “off-books” parts for months. Mostly plumbing fittings. Some very… modular pipe barrels. One even had threading that matched a firearm suppressor.

“Who the hell’s been printing this?” Lima asked.

Evie and Jonas exchanged looks.

Lima got a sinking feeling.

“It was me,” Jonas muttered. “I just… I didn’t think it would flag the system. I only did it a few times. It was barely illegal.”

Lima blinked. “Barely illegal? What is that, like… diet crime?”

“It was for my cousin’s startup,” he added weakly. “Crypto parts exchange. Real hush-hush.”

Lima looked around the sealed, silent factory.

“Yeah. Very hush-hush.”

V. Union Chat and Fire Doors

Evie sat down on a spool crate. “You know, the Union’s gonna have a field day with this.”

“The union?” Lima asked.

“Yeah, Local 674. Covers part-time automation workers and ghost factory staff. We’ve got a legal fund now.”

“What exactly would they say here?”

“That security lockdowns shouldn’t trap workers inside without ventilation. That ops training doesn’t include dodging rogue security scripts triggered by dumbass side hustles.”

Jonas raised a hand. “In my defense—”

“No,” Evie said, and didn’t look at him.

They all sat in awkward silence. The factory was getting warmer.

VI. The Call Is Not Coming From Above

At 12:03, Lima’s slate blinked back to life—sort of. A backup signal pinged from an old maintenance device plugged into a corner panel. She had 2% battery. Enough for one message.

She considered calling Roy.

She really, really considered not calling Roy.

She pinged Maya, an old friend from uni who now freelanced as a systems contractor for post-automated warehouses. Lima typed:

“Hey. Weird Q. How do I reset a locked-down factory with no master override, no uplink, and a staff member who might have low-key printed illegal stuff for crypto plumbing bros?”

Maya replied:

“Oof. Is this another Jonas situation?”

“Same Jonas.”

“Classic.”

“Please help.”

VII. Gracefully Unqualified Solutions

Maya walked her through an old exploit—the kind everyone knew but never used because it required a barcode scanner, a food item, and a biometric double-auth.

Lima remembered the emergency nutrition dispenser. She found it, jammed a protein bar into the barcode tray, forced Jonas to scan his thumb and then used a spare console Evie jury-rigged with the jewelry laser cutter.

The system, in a stroke of absurdity, registered the act as an “Authorized Wellness Override.”

The doors unlocked.

No fanfare. No victory music.

Just a faint “ding.”

VIII. Exit Interviews

By 3pm, the police had arrived. They were surprisingly relaxed—apparently, ghost factory crypto crime was more common than anyone admitted.

Jonas was cuffed politely. “It was just pipe stuff!” he insisted.

Evie gave Lima a look. “You didn’t know what you were doing, did you?”

“Not a clue,” Lima said.

They both started laughing.

Later that evening, Lima wrote up the incident report. Roy called mid-way through.

“Everything okay in Nunhead?”

Lima paused.

“Yeah,” she said. “Just one of those days.”

She saved the report.

Then she ate the misprinted sprocket Jonas gave her. It was made of biodegradable protein plastic and vaguely bacon-flavored.

End.

🏭 Ghost Factory (est. ~2035)

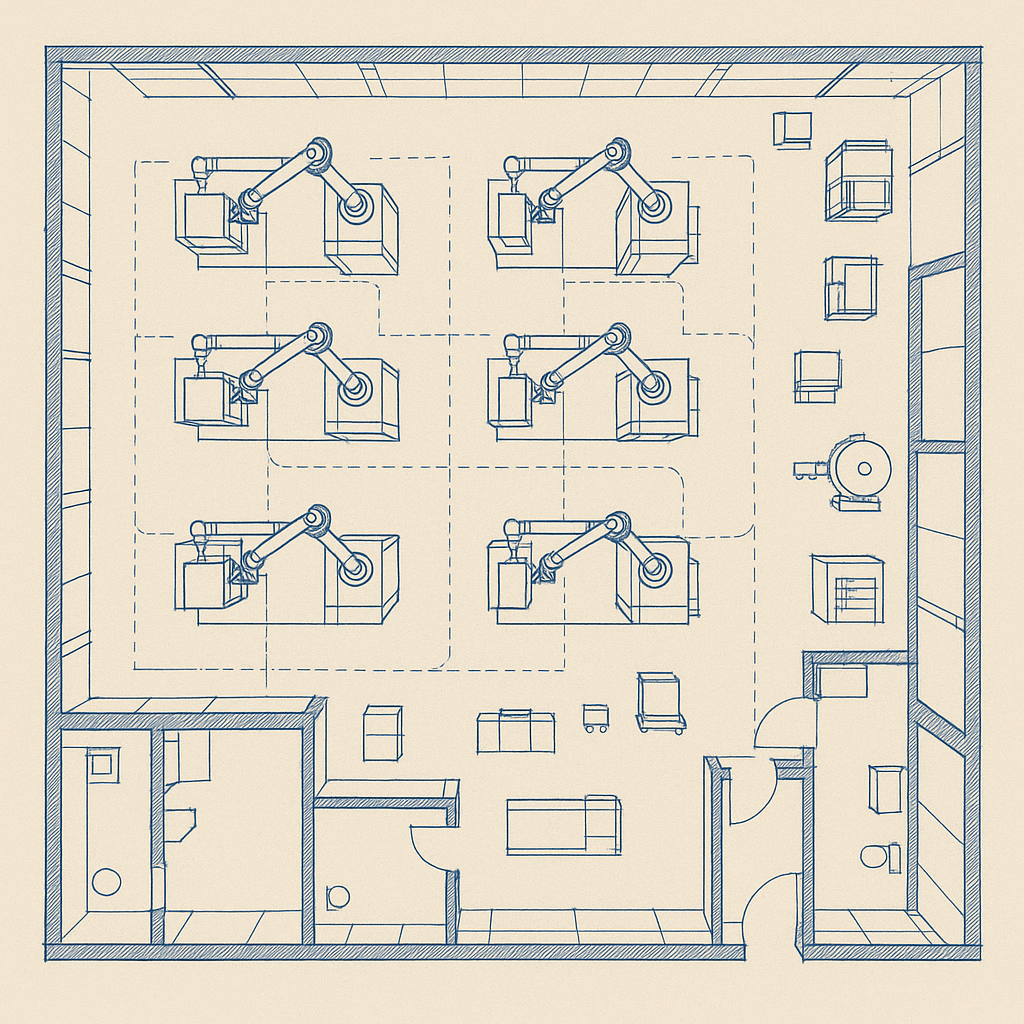

A Ghost Factory is a compact, semi-autonomous manufacturing facility designed to operate with minimal human presence. Typically powered by renewable energy and equipped with advanced 3D printing, robotics, and remote monitoring systems, these factories produce small-batch or on-demand goods—often mechanical spare parts—without traditional assembly lines or large workforces.

The term “ghost” emerged around 2035, referencing the stark emptiness of these facilities compared to their industrial ancestors. Where traditional factories once buzzed with hundreds of workers, ghost factories operate silently with just one or two onsite staff for oversight, while most operations are managed remotely. The ghost isn’t a haunting—it’s a whisper of a new industrial normal: decentralized, modular, and eerily efficient.

| Category | Details |

|---|---|

| Service Type | Distributed, modular, semi-autonomous manufacturing unit |

| Core Offering | On-demand 3D-printed mechanical spare parts (e.g., discontinued components, vehicle parts, plumbing elements) |

| Factory Size | ~10,000 sq ft per unit |

| Power Source | Off-grid (solar with backup battery + hydrogen fuel cell where available) |

| Tech Stack | CAD-based design queue, industrial 3D printers (multi-material), IoT monitoring, remote override system, secure network tunnel, basic AI for queue optimization |

| Revenue Model | B2B orders via API or platform (subscription + per unit pricing), long-tail fulfillment for legacy machinery, white-labeled printing for large manufacturers |

| Cost Structure | High fixed cost (setup, tech stack), low variable cost per unit due to automation |

Essential Operations

| Stage | Processes | Tech Used |

|---|---|---|

| Order Intake | CAD file submitted via central system or client API | Order management system, design validation software |

| Print Queue Management | AI allocates printer slots based on material, urgency, and calibration | AI scheduler, digital twins |

| 3D Printing | Industrial-grade additive manufacturing process | Multi-material printers, real-time sensors |

| Post-Processing | Cooling, finishing, and quality check | Automated inspection tools, sometimes human oversight |

| Packaging & Dispatch | Part packed, labeled, queued for pickup | Barcode scanner, automated sorter |

| Shipping & Handover | Courier collects, delivery tracking starts | Courier API, geofence confirmation |

Team Shape

| Role | Description | Avg. Per Factory |

|---|---|---|

| Technical Steward (Evie) | Oversees CAD uploads, validates jobs, light maintenance, inspection | 1 |

| Ops & Security Lead (Jonas) | Receives materials, loads printers, dispatches parts, monitors premises | 1 |

| Maintenance Crew (mobile) | On-call technicians for deep repairs (shared across sites) | As needed |

| Factory Manager (Lima) | Oversees 5–10 factories, site visits every 2 weeks, manages issues | 1 per region |

| Remote Support (HQ) | Software patches, AI training, queue optimization, compliance | Centralized |

Essential Journeys

| User | Journey Step | Trigger | Goal | Tasks/Actions | Pain Points | Opportunities |

|---|---|---|---|---|---|---|

| Lima (Factory Manager) | Weekly site visit | Calendar schedule | Check operational status & staff wellbeing | Tour facility, review logs, meet staff, flag system issues | Information gaps from remote logs, delayed alerts | More predictive dashboards and staff check-in summaries |

| Emergency Response | System alert / staff call | Contain threat, protect staff, escalate properly | Investigate issue, communicate with HQ, attempt overrides | Unclear protocols, poor tools, no live support | Onboarding for complex scenarios, “ghost protocol” playbook | |

| Staff Oversight | Management KPIs | Keep factory safe, compliant, and productive | Review productivity, investigate anomalies, submit reports | Too much admin, disconnected from daily ops | Unified staff and machine performance reports | |

| Hardware/Software Debug | Printer/system malfunction | Get system running again | Coordinate remote support, assist onsite fixes | Low technical depth, poor hardware documentation | Remote guided AR/manuals, escalation chatbot | |

| Evie (CAD Steward) | Starting a shift | Arrival/check-in | Ensure printers are loaded, ready, and clean | Scan dashboards, run machine checks, update firmware | Redundant checks, time pressure | Smart alerts & checklist consolidation |

| CAD File Upload | Order comes in | Load correct specs for print job | Validate file format, assign printer, monitor job | Confusing file naming, version conflicts | File validation AI, automated backups | |

| Unexpected Print Error | Print job fails or misbehaves | Resume or reprint safely | Check logs, pause print, inspect hardware | Blame games, downtime stress | Peer-reviewed fix library, Slack-style diagnostics board | |

| End-of-Day Report | Shift end | Log work done, flag issues, clean workspace | Upload shift report, review print metrics, inventory scan | Reporting fatigue, lack of recognition | Smart summary generator, “highlight reel” tracker | |

| Jonas (Ops + Security) | Morning Inventory | Delivery arrives | Load materials, secure inputs | Check delivery manifest, barcode scan, stack supplies | Tedious work, messy supply labeling | Modular trolley system, RFID restocking prompts |

| Outbound Shipping | Print completed | Prep & send deliveries | Box prints, assign courier, scan out | Courier delays, missing labels | Live courier ETA tracking, auto-print shipping slips | |

| Lockdown Response | Factory security trigger | Stay safe, wait for unlock | Follow lockdown SOP, assist others | Confusion, lack of protocol knowledge | Gamified safety drills, “lockdown buddy” checklist | |

| Side Hustle (unauthorized) | Personal gain | Make extra money | Queue personal files, hide logs | Legal risk, system flagging | Clearer rules, safer side-work channel (legal/approved) |